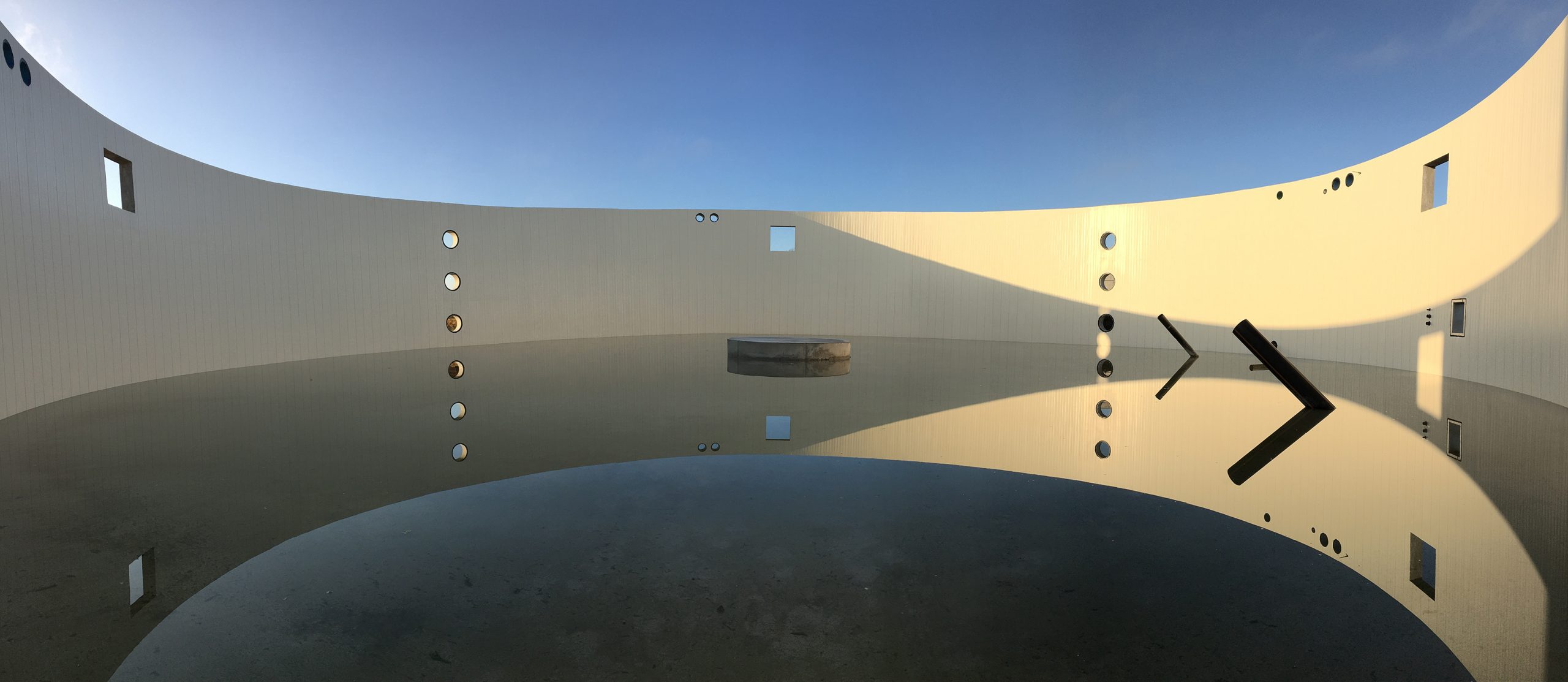

The concrete forming system

FormProtect is a stay-in-place concrete forming system, which in the finished state becomes a reinforced concrete composite structure. High-quality and proven PVC modules form the foundation.

The construction of the acid-resistant plastic profiles is based on the modular principle and thus differs significantly from the conventional construction method: The various profiles of the FormProtect system are plugged into one another.

The result is a solid and stable network that provides clients with numerous advantages when building different structures.

This is how the reinforced concrete tank is created with the FormProtect concrete forming system

Construction and statics

Due to the high strength and the delicate spatial stiffening of the plastic elements, a very pressure-resistant and flexurally stiff component is created in reinforced concrete composite construction. The high flexural rigidity of the shell also allows for moments, for example from earth pressure loads, which ensures a high level of security against earthquakes.

The main load on the container wall consists of the container filling load case, which essentially only creates ring tensile forces. The general load-bearing behavior of the formwork system with the inserted steel bar reinforcement is comparable to the load-bearing behavior of a wall construction made of prefabricated parts with tendons.

The distance between the horizontally inserted reinforcing steel bars can therefore also be more than 35 cm. The requirements in DIN 1045-1: 13.7.1 (7) for reinforced concrete walls are not to be complied with here.

The formwork system achieves a complete separation between the load-bearing and protective functions of the structure. The plastic formwork becomes part of the structure and thus, from a functional point of view, the overall construction consists of three container shells in one wall – the plastic shell on the inside, the reinforced concrete wall as the core and the plastic shell on the outside.

The plastic shells alone guarantee tightness, corrosion protection, protection against chemical attacks and the other protective properties mentioned above. The reinforced concrete structure only takes on the load-bearing function. With the reinforced concrete structure being protected on both sides by the plastic shells, the limitation of the crack width is of no importance. Nevertheless, the reinforced concrete core remains essentially free of cracks as it cannot dry out.

The walls are made with a single-layer horizontal reinforcement made of round steel up to Ø 16 mm. There is no static connection between the floor slab and the wall. The floor / wall joint is sealed with a joint tape approved by the building authorities.

With the FormProtect formwork system, buildings are created with sophisticated technology and the highest demands.

Quality characteristics

The FormProtect system guarantees an exceptionally high quality in every respect.

Technical information

You can find detailed technical information on the FormProtect system in our download page.